Last firing the bead on a wire handle drooped on the pot next to it and the glaze fused them together. I used a handheld propane torch to heat up the glaze to separate them. If a piece sticks to the kiln shelf you can also use this method of heating the glaze and melting it to separate it from the shelf. Careful not to touch the part you heat because it stays extremely hot for a very long time.

I loaded this bisque last night and it is cooling; it's down to 532. Seems like it takes forever for the last 500 degrees to cool. I had two tall sculptural pieces which won't stand up on their own that so I propped them with stilts. I have no idea what I will do when I glaze fire them. I may make a pedestal tray with a pocket for them to rest in. What do you think, have any creative ideas of what to do?

Several people asked exactly which program I ended up using for my last firing. Here it is. I ended up putting the top peep in at 770 degrees but next time I will put the top peep in when the final fire down of 1400 is reached and the kiln shuts off. Here is the cone pack for the bottom shelf. Somehow I put the cones in reverse order so going from left to right is cone 6, cone 5, cone 4. The top shelf cone 6 was barely tipping, so it was cooler. The last photo in my previous post shows the inside of the kiln after firing. Judy at Mountain House Studios has given me some great advice about keeping firing logs and details about the cones and the placement of pieces of work in the kiln. I'm starting a separate firing book.

It took me forever to glaze the saguaro vase. I wanted the depressions to have a darker glaze and the ridges to be lighter. I paint each glaze with a small paint brush. Hope all the time it took is worth it.

We went to the big box store today to get a few items and I was drooling in the tool section at the paint guns. Gary already has an air compressor. I almost have Gary talked into getting a sprayer. It has a gravity fed paint reservoir and I can just imagine myself spraying glazes. Gay at Sister Creek Pottery gave me some good hints on spraying glazes so I can't wait to try them out.

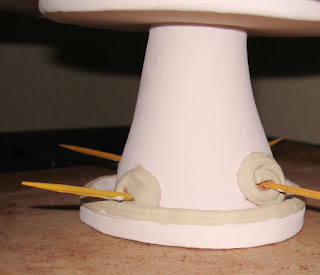

The cake pedestal is solid at the bottom and I put four holes (I always put more than one just in case) to allow air and gases to escape during firing. When I glaze the piece I temporarily put a toothpick in each hole to keep the glaze out.

If the kiln cools down in time I'll start another glaze firing tonight. Comments and suggestions are welcome.

I like your firing schedule for the last bit of heating and the slow cool, but unless you are once firing glazed greenware, you can fire faster than that, there is no need to hold at the boiling point if you have bisque fired these pieces. Well, unless you have very very thick walls, but from your pictures, I do not see anything that needs that slow warm up....just my 2 cents of course. I just fired a load that started with a ramp of 333/hr to 2000, then slow to ^6 then slow cool much like yours.

ReplyDeleteLinda, I have a Paasche air brush for spraying glazes, works really great. I think most ceramic supply places have them. You get a totally different look when you spray on glazes sometimes that's a good thing. We sprayed Raku glazes on work at Penland and got some very cool results. You definitely should give it a try!

ReplyDeleteAs far as holding up the sculptural pieces during the glaze firing. When I glazed my canteen and I wanted glaze on all sides, I used a stilt with medal prongs. The piece was laid on it's side. I only fire to cone 5 so it worked fine for me. I had been told not to use them during glaze firings, and the piece will be attached to the wires but you can tap the stilt with a rubber mallet and it will come right off. I use them when I make my ladles as well. You would want to smooth with a drummel afterwards.

ReplyDeleteLinda, Highwater has a siphon feed gun for $30 that works fine.Since the mixing is external, a siphon feed gun is easy to clean just remove the cup dunk in a bucket of water and spray.They are less prone to clogging and if you swap out the lid for one from an 18oz pnut butter jar you can have lots of spare jars for nothing.

ReplyDeleteHi Pam, thanks, we have so much humidity here and I figure the glaze adds back moisture into the pot, so better safe than sorry. I want to avoid blowups. My work is handbuilt and I didn't use a slab roller for this work so some pieces have uneven walls. My bisque was cooler than 04 so for the next few glaze firings I will keep with this schedule. The saguaro vase shown is very thick and heavy; I don't want it to blow up. Thanks again, I will slowly make adjustments to my firing schedule.

ReplyDeleteHi Tracy, thanks I look forward to trying it, especially for flat pieces like plates; brushing takes forever.

Hi Judy, thanks, I knew about stilts and never thought of that, thanks for the tip. I will check the next time I am at the pottery supply to see what they have. I have one other piece I have already glazed all over so the stilts would be perfect. Both of these pieces are so tippy; I don't know what I was thinking when I made them; these things just seem to make themselves somehow and then later create challenges for me. At least I'm learning along the way. Ha, thanks again.

Hi Dennis, thanks, I'll check it out. Gary wants to spray the bottom of our motorhome, so I thought I could use it too. It has a top feed plastic reservoir I thought I could use, but perhaps the tip is too small for glaze, probably; I'll check it out.

Hi Linda..thanks for posting the firing schedule. ( I commented back to your help on my post, so please check that out)..I like that you show the pieces in the kiln. What are the long flat 'curvy' pieces? Good to receive info on the sprayers too. I do not have one either, but would like to try.

ReplyDeleteLook forward to the next results. T.